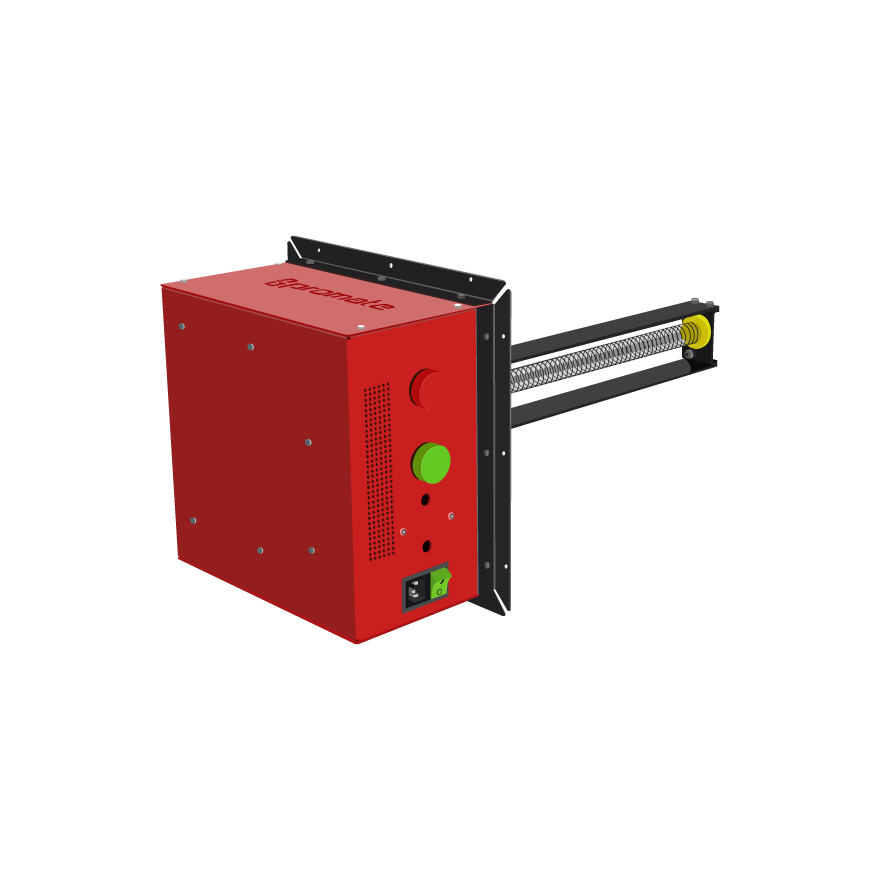

Researched, developed and made 100% in Turkey by the R&D dept. of Alize engineering, duct type stationary plasma filter units are advanced and latest technology devices, designed specifically to remove almost and disintegrate all of the food smells that occur inevitably during cooking process in industrial kitchens.

Our new product, the self-cleaning Aquabright Autowash electrostatic filter, has been put into use.

https://www.youtube.com/watch?v=sb1mi–kbZM

You can find details about our product from the links below.

https://alizemhs.com/urunler/tekil-urunler/aquabright/

In the plasma filter operating test performed at room temperature, it was observed that the temperature value in the tubes and wires of the plasma filter did not exceed 33.4 °C. Since the melting temperatures of the materials used in the manufacture of the plasma filter are much higher than this value, it does not cause combustion, oxidation or any deformation in the ozone production process. Therefore, the life of the plasma filter is guaranteed as a minimum of 120 + months excluding usage errors.

Melting Temperature of the Material Used

| Steel | 1.500 °C |

| Silicone | 350 °C |

| Lab. Glass | 820 °C |

Plasma Maximum Temperature 33.4 °C

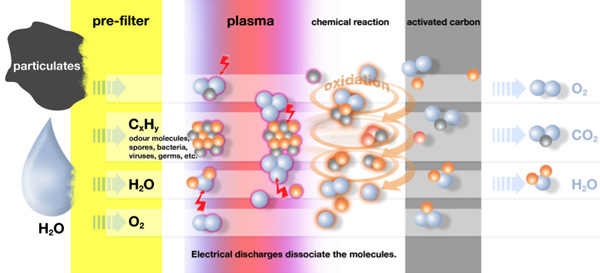

Efficiency: Organic carbon compounds that emit a small, malodorous microscopic area in the air reaching the plasma unit are destroyed by releasing high-density ozone (O3) into the air at this stage. Thus, a series of chemical reactions take place on these molecules, and the odor filter yield is between 95% and 99%.

Lifetime: If the maintenance is done properly, the active life is 120.000 hours. Plasma filters are long-lasting, no replacement required. It can only be used for many years with regular cleaning.

Energy Consumption: The energy consumption of the plasma filters is very low compared to other systems which claim to destroy the smell of the same amount. The plasma system is an environmentally friendly system.

Operational Cost: The ultimate in technology, this system works reliably and simply, allowing long-term plasma filter tubing to operate for long periods without maintenance, reducing operating costs as much as possible. Compared to other ozone (O3) producing technologies, it is seen that the operating cost is close to zero.

The new product from Alize Engineering’s exhaust filter system, the duct-type plasma filters, is a high-tech, air-sterilizing product designed to remove virtually all of the cooking smells that occur during cooking in industrial kitchens.

The high-purged air from the oil pan and the duct is subjected to a series of reactions as it passes through the plasma filter. Ozone (O3), positive ions formed in the plasma filter, oxidize odorous organic gases and vapors and destroy them by molecular reaction. Plasma-generated ozone (O3) destroys the smell in 0.5 seconds and is able to destroy odor molecules very quickly.

Odor elimination with ozone (O3) gas is defined in odor elimination techniques in order to reduce odor emissions at Annex-1 A 8,5.

The Ministry of Environment and Urban Planning of the Republic of Turkey has a legal limit of 1,000 OU (odor unit9 for waste odor.

The tests which we done at Dokuz Eylul University, which is an independent institution, prove that we can reduce the waste smell to 60-100 OU (odor unit).