Indoor Air Quality

More than 2000 pollutants pollute indoor air. Cigarette smoke contains over 600 toxic compounds. Other sources of pollution are mites, pollen dust, mold spores, pesticides, paints, solvents, and cleaning materials found in homes, and pets. Additionally, organic and inorganic particles and volatile organic compounds (VOCs) are also pollutants of indoor air. In the past, normal outdoor air infiltration was a factor that helped reduce indoor air pollution. However, inflation in energy costs in the 1970s naturally necessitated insulation in all types of structures and buildings, reducing the supposedly positive effect of outdoor air infiltration. As a result, air pollutants reaching concentrations above natural levels and threatening health in homes and commercial buildings have brought about the consequences of illness and disease in humans. Thus, the term Sick Building Syndrome has taken its place in the literature as a concept describing the excessive concentration of indoor air pollution in residences and buildings.

Health Effects of Poor Indoor Air Quality

The physiological consequences of bad indoor air can generally be listed as allergic reactions, headaches, nausea, and irritation in the nose, throat, and lungs. In addition, it can be said that discomfort and fatigue are common effects. Poor indoor air quality puts an extra burden on the body’s immune and defense systems, so energy loss and decreased productivity are obvious results. The long-term effects are still being investigated. The highest risk groups are children, the elderly, and those with respiratory and immune system diseases (asthma, emphysema, allergies). No one is immune to the effects of toxic substances at high levels. Substandard air quality always creates feelings of unwell-being for everyone.

Methods to Improve Poor Air Quality

There are three ways to improve indoor air quality (IAQ).

- Keeping the source of pollutants under control,

- Ventilation with fresh outside air

- Air cleaning.

1. Control of the source of pollutants can be achieved by limiting or eliminating the emission of specific substances into the air (prohibiting smoking and reducing humidity to prevent the growth of mold and bacteria).

Building materials and finishes are potential emitters of harmful substances. Harmless materials have been identified and are being developed to replace them. However, indoor air pollution has continued to increase for years with currently used materials and new finishes.

2. Ventilation with fresh outdoor air dilutes pollutants and brings them to a certain level. However, this is only possible if the outdoor air that replaces the inside air contains much less pollutants. In determining indoor air quality problems, the following definition was made under the leadership of ASHRAE (American Society of Heating Refrigeration Air Conditioning Engineers). It is necessary to think of a minimum of 5 to 15 cubic feet (cfm) of fresh air flow per person in an office environment. Also, ASHRAE’s standard for a home environment is 0.35 air changes per hour.

On the other hand, air cleaning provided by ventilation with outdoor air brings an additional load and power increase to air conditioning and heating systems, thus increasing energy consumption.

3. Air purification means eliminating the increase in airborne dirt and pollutant concentration in indoor air. Air purifiers remove a certain percentage of pollutants from the air volume over a given period of time. The percentage of pollutants removed from the air is expressed as the effectiveness of the air cleaner. The volume of air exposed to the air cleaning process is sized in cubic feet per minute or cubic meters per hour. For example, an air cleaner with a clean air preparation volume of 75 cfm (Cubic feet per minute) prepares indoor air by creating a mixture that will provide 75 cfm of clean air with a pollutant concentration in the air. This means providing a mixture that eliminates the concentration of pollution in indoor air. Using metric terms, the same air cleaner dilutes the pollution in indoor air by providing 125 cubic meters/hour of clean air.

The Importance of Particle Size in Measuring Air Cleaner Effectiveness

There are three reasons why air cleaner effectiveness is measured using the 0.3 micron DOP test.

- 0.3-micron particles are particles that can be inhaled and mostly accumulate in the lungs.

- K.W. Lee and B.Y.H. Liv of the University of Minnesota reported in April 1980 that the most difficult particles to filter from the airflow were 0.3 microns in size and

- Other test methods than the DOP test give less realistic results than the DOP test regarding the retention of particles of respirable size. Particles larger or smaller than 0.3 microns are easier to filter than those of 0.3 micron size. Testing a filter with 0.3-micron-sized particles is the best indicator for defining filtration efficiency and capability. DOP (dio clyphthalete), known as testing the 0.3-micron particle filtration efficiency, is performed with 0.3-micron-sized particles that are the result of thermal-based increase and this test is an excellent indicator of the effectiveness of filtration.

What Does Air Cleaner Effectiveness Mean?

Air cleaners are devices that clean the air by removing a certain percentage of pollutants from the environment. If we explain the term RSP that will be used in our statement here: it is an abbreviation formed from the first letters of the words Respirable Suspended Particles and refers to respirable particles in the air. This efficiency is expressed as the percentage of 0.3 micron RSP particles that it can remove from the air and the volume of air supplied to the environment. The most realistic indicator to use in comparing air cleaners is the clean air exchange rate measure known as CADR (Clean Air Delivery Rate). CADR criteria include the net air volume produced by the air cleaner system and the minimum filtration efficiency based on the 0.3 micron DOP test. To achieve this efficiency, an air cleaner with an efficiency that will remove 95% of 0.3-micron particles from 100 cubic feet (26.6 cubic meters) of air per minute would be said to require a (1680 cubic meters per hour) 95% DOP filter.

In summary: If 95% clean air is obtained from 1680 cubic meters/hour of air, 1596 cubic meters of clean air is obtained per hour. If we remember that this is 100 cubic feet per minute or 26.6 cubic meters/minute of clean air, so 1596 cubic meters / 60 minutes = 26.6 cubic meters/minute is obtained. The same result can be achieved from an air cleaner with 190 CFM (3190 cubic meters per hour) and 50% efficiency (based on 0.3 microns).

It should be remembered that the odor, vapor, and gas collection efficiency is also a time-dependent function with the vapor contained in 3190 cubic meters/hour x 0,5 = 1595 cubic meters/hour ambient air and the absorbency capability provided by an absorbency surface. It is also necessary not to forget the temperature, humidity, and odor factors that affect the efficiency.

Effects of Air Flow Characteristics on Air Quality

Clean air can be discharged from the air cleaner in a single direction (laminar airflow) or in multiple directions (omnidirectional flow). In laminar air flow, dead zones may appear in the room and the air in these zones may remain quiescent wherein pollution may continue to exist. In air cleaners that provide omnidirectional discharge, the level of pollutants in the air is reduced homogeneously throughout the area with clean airflow. In addition to this, multi-directional flow creates a low pressure in the unit, facilitating the flow of dirty air towards the inlet of the air cleaner device.

Types of Air Cleaners

Air cleaners come in four different principles:

- Those with mechanical filters

- Those with electrostatic filters

- Electrostatic precipitators

- Ionizers

Let’s briefly explain these types:

1. Mechanical Filtration Type:

These fiber or foam-type filters filter and eliminate particles from the air. These devices do not contain any electronic parts and the effectiveness of these types of filters does not decrease with use. The RSP (Respirable Suspended Particles) efficiency of holding respirable particles in the air ranges from 2% as in standard furnace filters to 99.97% efficiency in HEPA filters.

2. Electrostatic Filters:

They are placed in static electricity charge with plastic fiber or strainer filters or are devices that provide static electricity charge with an air outlet. This static electricity charge attracts and holds particles as if they were passing through a filter. RSP efficiency range is from 7% to 97%.

3. Method of Electrostatic Precipitator:

These systems consist of two stages. In the first stage, the air is ionized by a high-voltage point or a cable, thus making the particles charged. In the second stage, the air passes through charged metal plates at high voltage, thus the charged particles are attracted and separated from the air.

In this type of device, the RSP efficiency decreases due to the contamination of the collector plates. The initial efficiency can be considered as approximately 95%, but depending on the duration of use, this decreases to 20% (for example, a 40-hour operating period causes this decrease). The initial efficiency is regained by cleaning the collector plates. This should be provided with regular maintenance.

4. Ionizers:

These units also clean the air by ionizing the particles and making them electrically charged, but they do not contain second-stage collector plates as in electrostatic precipitator types. The charged particles separate from the air and stick to the first charged surface, similar to polishing a wall. Naturally, this creates a pollution problem and also the risk of particles losing their static charge and becoming airborne pollutants again. There is no RSP data recorded for this type of device. Also, sometimes they produce unsafe levels of ozone.

Some Tests Conducted on the Performance of Air Cleaner Devices and Their Results

1. Robens Health and Safety Institute (UK):

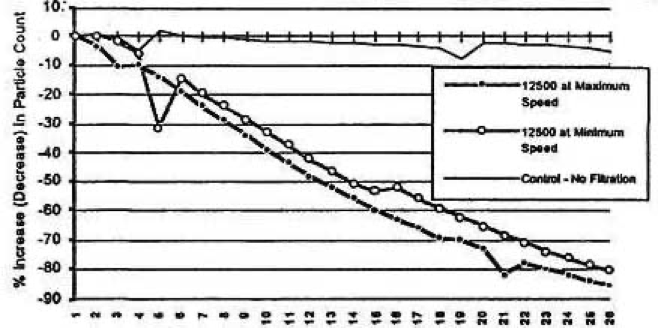

An air cleaner selected for this purpose has been tested by the Robens Institute of Health and Safety (UK). The device was built in a 20 cubic meters closed room wherein the effects of smoking were tested. Three separate tests were organized. One of these is to monitor the particle concentration change for 30 minutes without filtration and the other is to operate the device at maximum and minimum levels and monitor the particle concentration. The results are as in Figure 1.

By operating the device at maximum speed capacity, 85.7% of the total particle amount was recorded to be eliminated whereas 80.8% particle elimination was recorded at minimum speed capacity. On the other hand, in the control experiment where there was no filtration or there was air circulation outside the device, it was

determined that the decrease in the total amount of particles in the air reached a maximum of 4.7%. These measurements are based on the total amount of particles in the environment after smoking and before the device is turned on.

2. Testing in a Work Environment:

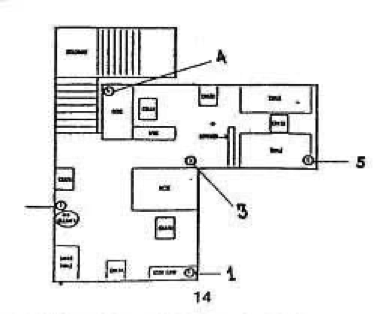

This test was conducted in the office in question to understand the cleaning effects and in a typical work environment. The test area was completely untidy and fully furnished. The total volume of the environment was 57.5 cubic meters (2,014 cubic feet) and the carpeted area was 27 square meters (291 square feet). The layout plan of the office is shown in Figure 2.

A portable laser particle counter was used for testing to count particles of 0.3 microns and larger. Five sample regions were selected. Devices were placed in the regions by selecting three types of heights. Air cleaners were placed on the floor (3), mid-height (2), and ceiling (1,4, and 5) with two clearly visible (1 and 2), two covered by walls (4 and 5), and one blocked by furniture (13). Particle counts were initially performed by counting the normal particle deposition at each site for 30 minutes after starting smoking.

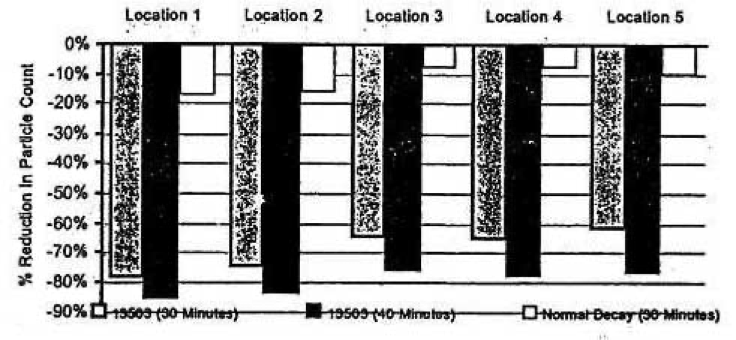

After this natural precipitation, additional cigarette smoke was added to the medium to ensure that the particle concentration remained at the same level for the beginning of the control test, and the particle amount was measured and recorded every minute for 30 minutes while the air cleaner was operating at maximum speed. An additional measurement was made after 40 minutes. The office doors were kept closed and all ventilation in the environment was closed during the tests. The placement of air cleaners in the environment was not done with the aim of obtaining maximum performance of the device but by random placement. These results were obtained by placing them near electrical outlets. Particle counts in the five zones decreased by an average of 12% (maximum reduction of 18% and minimum reduction of 8%) during 30 minutes without filtration (normal settling). After 30 minutes of operation of the air cleaner, the particle reduction was 69% on average (maximum 79% and minimum 62%). After 40 minutes of operation of the device, the particle reduction was 80% on average (maximum 86% and minimum 76%). These results are shown in Figure 3. The clear statement of the design and the experimental results is that the amount of elimination of ambient pollutants during the operation of the air cleaner is much higher than the normal precipitation situation. Another result is that the level of cleanliness in the more restricted areas reaches the same level as in the unrestricted and openly placed devices within a 5-7 minute delay. It can be concluded that the rate of decrease in particle amount is approximately similar in all regions.

Reference

Compiled from Honeywell Air Cleaners Sales & Applications Information.

İ. Deniz YILDIRIM

He graduated from YTU Mechanical Engineering Faculty in 1986 and has been working in Production Planning at Alarko Industry and Trade Inc., Planning at STFA Sedef Ship Industry Inc., Product Management at Erensan Heat Industry Inc. and for two years, Residential Control and Automation at Honeywell Inc. He was born in Istanbul in 1965 and speaks English.