As Alize Engineering, we provide CFD-based analysis services on the design of air ducts, hood performance and energy efficiency within the scope of Industrial Kitchen Ventilation, which is one of the leading items in the HVAC sector.

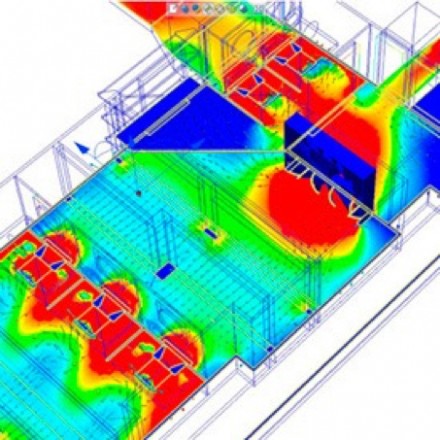

The measurements taken according to the kitchen project are transferred to the analysis program. The hoods, appliances, fans and ducts in the kitchen are also positioned according to the kitchen project. The performance of your current kitchen design is evaluated according to the analysis results.

After these processes are completed, what should be done by both the business and our company is shared with the business and reported.

What is CFD Analysis?

CFD (Computational Fluid Dynamics) is a branch of fluid mechanics in which the problems in which fluid behavior is effective are analyzed by solving them on a computer with numerical methods and algorithms. Thanks to the developments on the software side, turbulent, polyphase and supersonic flows can be easily modeled.

CFD, which has a wide range of uses from the automotive industry to aerospace, electronics, environmental, energy and medical applications, can provide us with detailed information about the following concepts and events;

- Steady regime or time dependent fluid behavior

- Pressure, velocity and temperature distributions

- Heat transfer

- Single and polyphase flows

- Constant density and compressible fluids

Accurate determination of fluid behavior is very important in engineering calculations. In complex models that cannot be calculated directly by analytical methods, the determination of data such as heat transfer, pressure losses, flow rates by numerical methods, while the part is at the design stage, provides significant advantages to the manufacturer in terms of time and cost.

CFD provides accurate and fast results in many applications such as multiphase flows, Newtonian or non-Newtonian flows, solid-liquid interaction analysis, advanced turbulence models, analysis of rotating parts.

CFD Analysis in HVAC applications

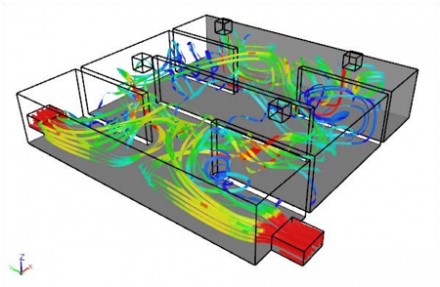

Computational fluid dynamics applications occupy an important place in the HVAC industry. As Alize Engineering, there are studies that we have done on this subject and it continues rapidly in new studies.

1. Industrial Kitchen CFD analysis

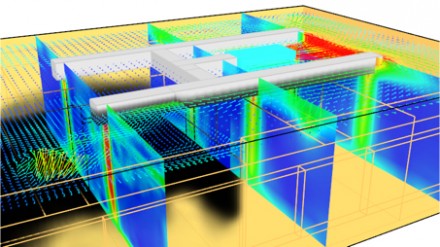

Distribution of air in ventilation ducts and optimizing the flow in industrial kitchens are very important in terms of energy efficiency.

The purpose of using electrostatic filters in industrial kitchen ventilation; The system operates in the form of collecting the polluted air resulting from cooking in the kitchen with the hood and exhausting it out through the duct. However, as the air moves through the duct, it encounters resistances originating from the duct design, so every obstacle it encounters creates a pressure drop. High pressure drops lead to the selection of fans that require greater power. Therefore, with the right duct design, the capacities will be reduced and lower energy consuming ventilation ducts can be designed.

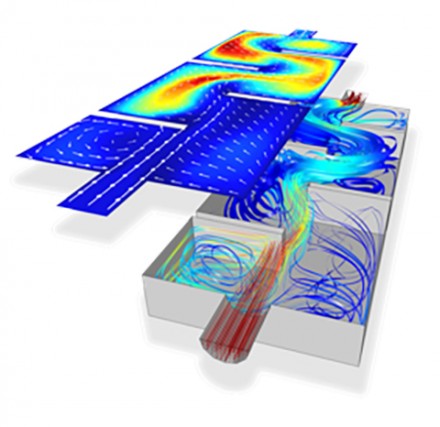

2. Ventilation Ducts CFD Analysis

You can do much more than evaluate the current state of your channel design’s performance with flow analysis capabilities. You can optimize, resize or reconfigure existing components in the duct design (e.g. elbows, diverters) to optimize the flow performance along the duct line, i.e. make it more laminar with using the results.

You can examine the fluid behavior in areas that are dangerous or inaccessible to observe in the channel. For example; You need to reconstruct a classical experiment for which you want to obtain pressure data for velocity measurement. However, with CFD, information on many more parameters, including speed data, is also included in the solution, so there is no need for a new simulation or troublesome setup.

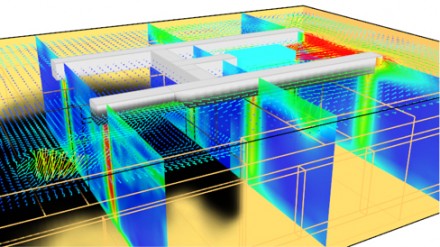

3. Hood Performance CFD Analysis

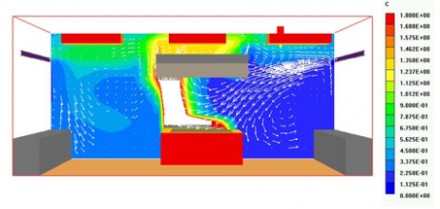

Choosing a hood is one of the milestones of the kitchen ventilation and air conditioning system.

The hood used in the Industrial Kitchen ventilation system is designed to store heat and odor. The system operates in the form of collecting the polluted air resulting from cooking with the hood and exhausting it out through the duct. Due to the food product being cooked, it is more or less audible to the environment and latent heat is emitted. In such operations, mainly oil, steam and particles are spread to the environment. At the same time, heat transfer takes place convectionally by being carried by air.

In hoods developed for professional use, the design and other desired adjustments must match the mounting dimensions.

The design performance can be evaluated with the analyzes that can be done before the production of the hardware by using CFD. In current designs, on the other hand, by detecting the wrong applications on the system, studies can be carried out on performance evaluation and energy efficiency. Therefore, designers and manufacturers can better understand product behavior in many applications with CFD.

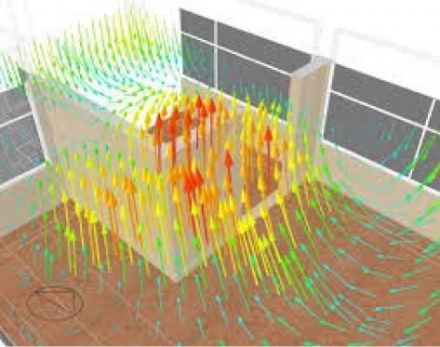

4. Fresh Air CFD Analysis

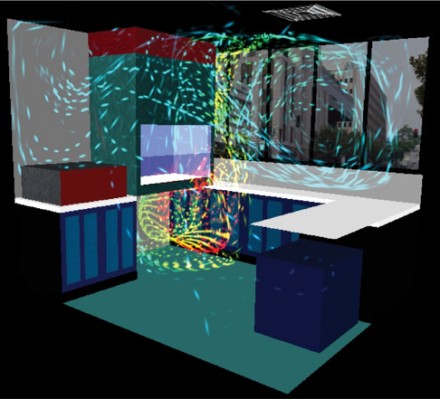

Working environments in people’s lives, especially in kitchens where cooking is done, have an important place in the quality of life. Creating a comfortable environment with minimum energy use is the goal of both space designers and users of the space. Both the comfort of the person and the energy use in the kitchen are highly affected by the way fresh air is provided.

While exhaust is made from the kitchen with the help of a hood, fresh air inlets are also made into the space. Even if a sufficient amount of fresh air is given to the kitchen environment, the air coming out of the cooking equipment under the hood may not be directed correctly and may escape out of the hood. The reason for this is the incorrect application of fresh air projecting. Since the delivery and distribution of fresh air plays a very important role in determining the kitchen environment; Accurate estimation of the air flow in the occupied area, the rate of air delivery and the structure of the fresh air system are milestones for an effective air distribution system design.

The air movement in the space can be estimated and therefore the hood performance can be evaluated with the fresh ventilation system CFD analysis. For example; By examining the air movement in a closed kitchen with air inlet from the ceiling and air outlet from the door or windows, the velocity and temperature distribution created by the flow created by the air entering and leaving the volume can be examined.