One of the main requirements for a successful restaurant design is a healthy ventilation system. The most significant part of the restaurant ventilation load comes from high-capacity hood exhaust flow rates. Heating the fresh air required to meet the hood exhaust flow rate in the winter months is a very serious investment and, more importantly, an operating cost. Due to the high-temperature values of the hood exhaust air, heat recovery systems always appear as an attractive alternative. However, there are important points to consider due to the high investment costs of heat recovery systems.

Compared to other commercial establishments, the energy consumption per m2 unit of restaurants is higher. Ventilation system expenses take a large place in this consumption. Ventilation system operating costs and recovery potential depend on factors independent of system design. Kitchen ventilation systems investment and operating costs depend on different parameters such as climate, working hours, equipment efficiency, and comfort level.

International requirements

ASHRAE Standard 90.1 requires one of the following options to be applied in kitchen ventilation systems with a total exhaust flow rate greater than 8,400 m3/h:

- 50% of the kitchen supply air should be transferred air that would otherwise be exhausted.

- There should be a heat recovery system with 50% efficiency.

- A demand-dependent variable speed system that can control at least 75% of the exhaust flow rate. This demand-controlled system should be able to reduce the exhaust air and, consequently, the fresh air supply by 50%.

The demand-based control of the exhaust system is intended to reduce the exhaust flow rate at partial loads and when nothing is being cooked. While effective suction from the hood is provided at partial loads, the fresh air flow rate should be reduced proportionally to maintain room-to-room pressure differences and air currents.

Reducing exhaust flow and air speeds in the duct does not have a negative effect on oil and soot accumulation on the duct surfaces. NFPA 96 gives the minimum air speed in the duct as 2.54 m/s. According to NFPA 96, another factor affecting oil and soot accumulation on the duct is the temperature difference between the air temperature in the duct and the duct surface. When the temperature difference increases, oil and soot accumulation also increases.

Combovento HR solutions

Heat recovery systems are more useful in areas where the outside air temperature is low. From our previous measurements, it was observed that the hood suction was sufficient at 40°C exhaust air outlet temperature values. At this temperature, the exhaust air seems attractive for heat recovery. However, the soot and oil in the hood exhaust air can cover the heat recovery surfaces and can even completely block them. Therefore, the necessary precautions should be planned in advance. During our applications, it has been seen that serpentine, run-around type heat recovery systems are more suitable due to both the layout problems, the possibility of using the recovered heat in different regions, and the ease of maintenance. With the selection program for air-to-water heat recovery with run-around type serpentine, the most suitable serpentine was selected for the entire serpentine air flow rate and low temperatures. The serpentine surface cross-section is the same as the surface cross-section area of the electrostatic filter. The device has been reduced to the smallest possible dimensions. The 2.5 mm fin spacing is the most suitable choice in terms of air-side pressure drop, heat recovery efficiency, and cleaning. The efficiency of each coil was compared in parameters such as different water side pressure drops, different water velocities in the coil, air velocities at partial loads, and different indoor and outdoor air temperatures, and a coil was selected to give the best result under all conditions.

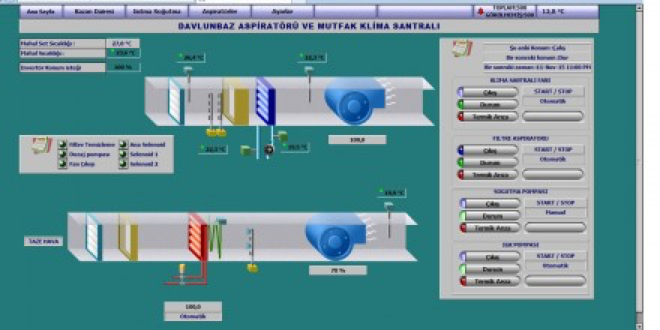

The automatic control panel proportionally gives the fresh air amount in response to the changing hood exhaust requirement. Each fan and duct system gives different reactions at different speeds. For this reason, driving the exhaust fan and fresh air fan with the same frequency value or a single ratio creates imbalances. The automatic control panel we have developed allows the fresh air fan speed to be adjusted differently at certain levels in

response to the different speeds of the exhaust fan, and the values in between are adjusted proportionally. Different frequency values are assigned to the fresh air fan at 5 different frequency values of the exhaust fan, and the fresh air fan provides the right amount of fresh air at each frequency value of the exhaust fan. Kitchen staff only adjust the exhaust flow rate, the appropriate amount of fresh air is set via the automatic control panel. Evaporative cooling can be used in restaurant kitchens because hourly air changes are very high.