AIRFLOW IN COMMERCIAL KITCHENS

It is imperative that every kitchen has a properly designed and manufactured ventilation system, and therefore every building with a kitchen must be designed with enough space for such a system.

Ventilation is necessary in kitchens and adjacent areas for the following reasons:

• Cooking appliances release significant amounts of heat through convection and radiation.

• Air is loaded with odors, oil fumes, and combustion products.

• Humidity increases over a large area during food preparation and washing.

• Air exchange and balance in adjacent areas and temperature must be kept at desired values.

• It is essential to provide an adequate supply of air in order to guarantee the complete combustion of fuel and ensure the safe operation of gas and solid fuel equipment. Details of these requirements are given in the Building By-law BS 6173 and the CIBSE B2 Guide.

The main emissions that need to be eliminated are:

• Hot air from the heat load around the cooking appliance.

• A moist environment consisting primarily of water vapor, oil, and cooking odors that are present in foods and turn into gas.

• Smoke containing particles.

• Exhaust fumes originated from gas, wood, or coal-fired appliances.

It is imperative that the level of fresh air provided ensures that the long-term exposure (LTEL) and short-term exposure limit (STEL) of carbon monoxide (CO) for kitchen personnel does not exceed the permissible limits set forth by the Control of Substances Hazardous to Health Regulations (COSHH) or the World Health Organization (WHO). The COSHH limit for CO is 300 parts per million (ppm) for 10 minutes, while the WHO limit is 10 ppm averaged over eight hours. Furthermore, it is imperative that the carbon dioxide (CO₂) concentration in the kitchen does not exceed 2800 ppm (IGEM/UP/19).

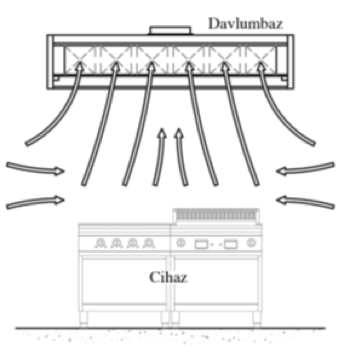

All cooking processes generate heat in a manner that is approximately 35% radiative and 65% convective. In the absence of cross ventilation, the heat migrates upwards in a thermal movement designated as a “Plume” (Figure 1). The presence of contaminants from the cooking food and the heat source causes the plume to expand with additional air, thereby reducing the average temperature and speed. It is imperative that the airflow expelled from the hoods incorporates both the plume generated on the cooking apparatus and the supplementary air volume specified in Table 2. Therefore, the resistance of the cross-air currents that draw away the plume (formed during the cooking process) will be ensured.

Figure 1 Airflow model

The calculation of the optimal air flow represents the most crucial aspect of hood design, as the presence of either an excess or deficiency of air exhaust will inevitably give rise to significant complications. The dimensions of the range/stove and the specifications of the menu dictate the dimensions of the hood to be utilized. The type of range/stove determines the exhaust air flow rate. The requisite air flow rates are provided in Table 1. The sole calculation method that should be employed is the “Thermal Transport Method.” A commercial kitchen where no cooking is conducted is classified as a “Preparation Area,” and 20 air changes per hour are sufficient.

Thermal Transport Method

This method is based on the procedure outlined in the CIBSE B2 Guide but has been expanded to encompass a more comprehensive range of equipment. The thermal convection coefficient must be applied following the specifications of the kitchen equipment to be ventilated. This value serves to determine the requisite exhaust air flow rate per square meter of surface area of the equipment, in cubic meters per second (m³.s-1.m-2). The total air flow rate to be exhausted is calculated by multiplying the surface area of each cooking unit located under the hood or ventilated ceiling by the thermal convection coefficient of that unit and then summing the resulting air flow rates for all units. The thermal convection coefficients of cooking equipment exhibit variability contingent on the operational fuel source, whether gas or electric. The aforementioned values are provided in Table 1 for reference. An illustrative example of an airflow calculation is provided in Table 3. It is only possible to obtain theoretical exhaust airflow rates in laboratory environments where there is no airflow. The type of hood or ventilated ceiling (including its location), as well as other factors that may affect air movement, can influence the amount of air required for exhaust. The reduction in airflow within a confined space during the cooking process necessitates a corresponding reduction in ventilation. In cooking units with open sides on four sides, a greater volume of exhaust air is required in comparison to units with open sides on only one side. Accordingly, the calculated air flow rates for cooking units, determined through the thermal convection method, should be multiplied by the corresponding hood factor, as outlined in Table 2, to ascertain the requisite exhaust air flow rate. In ventilated ceiling applications, it is essential to consider the evaluation of the “active area” as the height increases. It is inadvisable to employ estimated factors in this context.

| Kitchen Equipment | For Hoods and Ventilated Ceilings | Surface Temperature | ||||

| Gas | Electric | |||||

| Flow rate coefficient (m3.s-1.m-2) | °C | |||||

| MISCELLANEOUS | ||||||

| Workbenches, Bone Saw and Stands | 0,03 | 25 | ||||

| Kitchen sink | 0,15 | 25 | ||||

| Pass Through Dish Washer | 0,4 | 61 | ||||

| Pan/Cutlery Washing Machine | 0,4 | 42 | ||||

| Dishwasher with Rack and Pass-through | See manufacturer’s doc. | 58 | ||||

| Coffee Machine | – | 0,03 | 25 | |||

| Light Duty Microwave Oven/Toaster | – | 0,03 | 25 | |||

| Bain-marie / Hot Cupboard | 0,2 | 0,15 | 57 | |||

| Electric IR Heater | – | 0,15 | 35 | |||

| Serving Counter for Hot Meals | 0,24 | 0,24 | 73 | |||

| Water Boiler / Pot Still / Soft Drink Unit | 0,25 | 0,2 | 78 | |||

| Cooling Unit | See manufacturer’s doc. | – | ||||

| Kitchen Equipment | For Hoods and Ventilated Ceilings | Surface Temperature | ||||

| Gas | Electric | |||||

| Flow rate coefficient (m3.s-1.m-2) | °C | |||||

| GRILLING | ||||||

| Low Carbon Steel Grill | 0,30 | 0,25 | 190 | |||

| Chrome Grill / Plancha | 0,45 | 0,40 | 290 | |||

| Induction Grill | – | 0,27 | 62 | |||

| Sandwich Maker / Panini Press | 0,45 | 0,34 | 105 | |||

| Upright or Chain Grill | 0,75 | 0,55 | 410 | |||

| Barrel Grills | 0,75 | 0,55 | 260 | |||

| Rotisserie (Not Solid Fuel) | 0,75 | 0,55 | 195 | |||

| Rotisserie Machine (for Kebab) | 0,75 | 0,55 | 195 | |||

| Charcoal Grill | 0,95 | 0,52 | 350 | |||

| Water/Vapor Grill (less than 16kW/m2) | 0,75 | – | 170 | |||

| Wok Burner (Induction) | – | 0,40 | 88 | |||

| Wok Burner | 0,90 | 280 | ||||

| Wok Burner (Turbo) | 1,00 | – | 370 | |||

| Type | Open on two sides | Open on one side | Closed on two sides | |||

| Low Level | 1,15 | 1,10 | 1,05 | |||

| Transition | 1,15 | 1,10 | 1,05 | |||

| Wall-mount | 1,25 | 1,20 | 1,15 | |||

| Wall-mount / Island Mount | 1,60 | 1,50 | 1,40 | |||

| Island | 1,35 | 1,25 | 1,15 | |||

Exemplary Flow Rate Calculation: Method 1

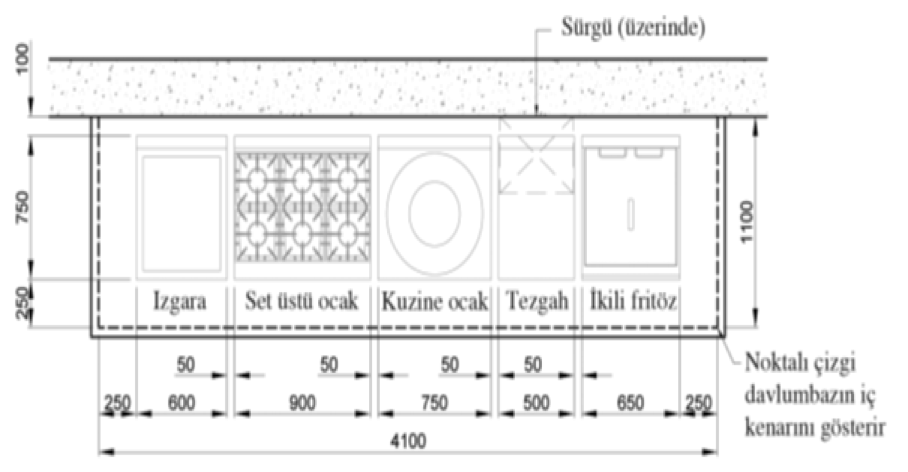

Figure 2 Typical cooking equipment design without oven

1. Determine the model, size, and energy source of all cooking units under the hood.

2. Determine the plan area and thermal convection coefficient for each cooking unit from Figure 2 and Table 1.

3. Calculate the theoretical exhaust air flow rates by multiplying the areas for each unit by the relevant coefficient.

4. Find the theoretical exhaust air flow rate for the hood by adding the exhaust air flow rates found for each unit.

5. Select the appropriate hood factor (Table 2) according to the hood type and location.

6. By multiplying the theoretical exhaust air flow rate for the hood by the hood factor, find the total exhaust air flow rate based on the application.

The calculation method described above can also be used for exhaust airflow for ventilated ceilings.

If high-heat-emitting cooking equipment generates “hot spots” in specific regions of the hood or ventilated ceiling, it is essential to consider the number and placement of oil filters to facilitate the extraction of greater exhaust air from this concentrated area. In such cases, it is of the utmost importance to ensure that excessive amounts of air do not pass through certain sections of the filters. It is essential to consider the dimensions and positioning of the supply air distribution and exhaust air collectors. The number and type of filters should be determined after the calculation of the requisite exhaust flow rate.

| Cooking Equipment | Plan Size (mm) | Energy | Area (m2) | Flow Rate Coefficient (m3.s-1.m-2) | Exhaust Rate (m3.s-1) |

| Grill (Low carbon steel) | 600 x 750 | Gas | 0,450 | 0,30 | 0,135 |

| Gas Oven | 900 x 750 | Gas | 0,675 | 0,40 | 0,270 |

| Range oven | 750 x 750 | Gas | 0,562 | 0,60 | 0,338 |

| Workbench | 500 x 750 | – | 0,375 | 0,03 | 0,011 |

| Double Fryer | 650 x 750 | Electrical | 0,487 | 0,45 | 0,219 |

| Barrel Grills | 500 x 400 | Gas | 0,200 | 0,75 | 0,150 |

| Required theoretical exhaust air flow rate | 1,123 | ||||

| Hood Factor – open on two sides, overhead wall type | x 1,25 | ||||

| Total exhaust air flow rate based on application | 1,404 | ||||

The DW/172 document, which has been prepared for the purpose of providing information pertinent to the specification of kitchen ventilation systems, offers a comprehensive and detailed account of the requisite calculations. The link is provided below for your convenience.

https://alizemhs.com/wp-content/uploads/2022/11/DW_172-1_compressed.pdf